As you crack open that nice cold brew, you may ponder where this delightful beverage comes from and how it gets from the brewery to your lips. Perhaps you know a little about brewing … isn’t there something about a mash and a boil in there? And hops get added at some point, too, right? But, if you’re not a home brewer or don’t take brewery tours on the regular, it can be easy to forget the ins and outs of how beer is actually made.

We had the opportunity to learn the step-by-step brewing process, thanks to the knowledgeable assistance of Greg Harris, director of brewery operations and head brewer at Levante Brewing Company.

From ingredient sourcing to the brew showing up at your summer barbecues, picnics and in your fridge at home, read on for detailed insight into how craft beer is made!

PA Eats: How do you develop the recipe for each beer creation?

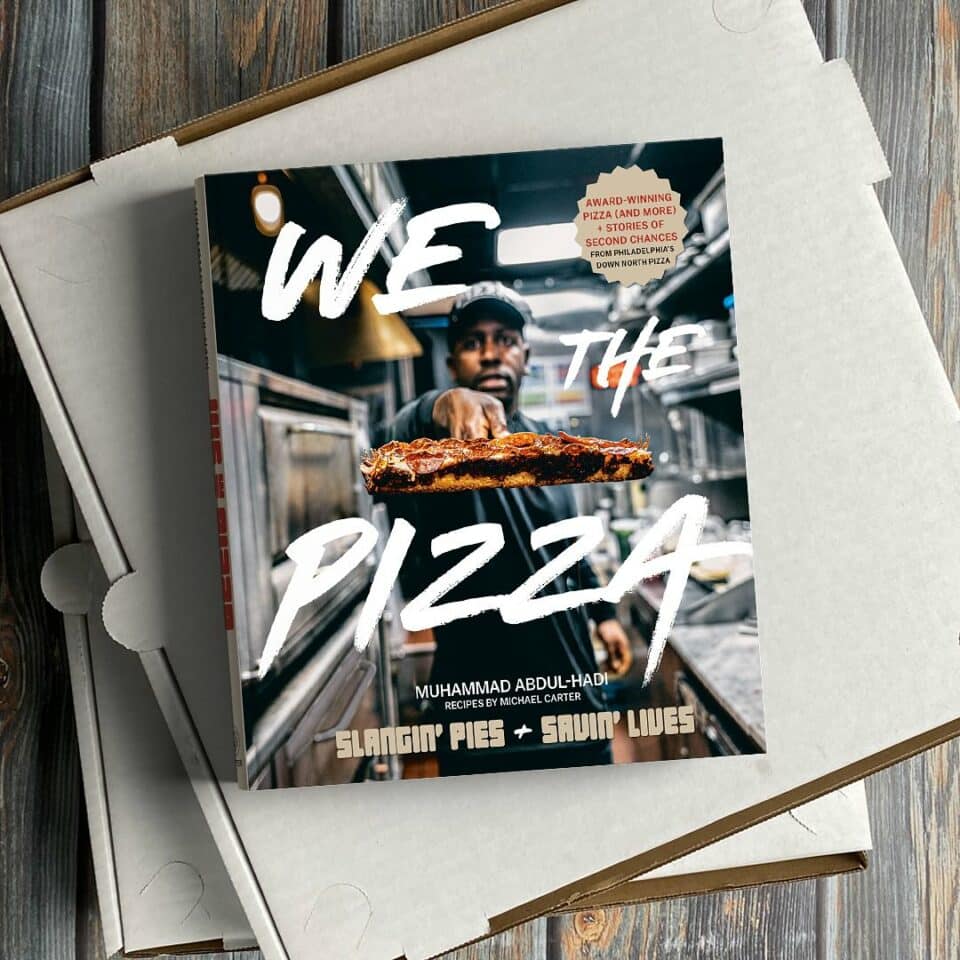

Greg Harris: The beer creation process starts with inspiration and concludes with care for the product and attention to detail. The idea for which beer/style you are looking to create is the first step. For us at Levante, the idea comes directly from inspiration, which can arise in a lot of different ways: from the culinary world, our travel experiences, experiences with our families and friends, drinking other beverages, and from other breweries that inspire us, to name a few.

Next, we take that inspiration and ask the following questions: What should this taste like? What ingredients will make up the flavor profile we are looking for and create a flavor customers will enjoy? What style of beer will this be? Once we answer some of these questions, I will try and visualize what the final product looks, tastes and smells like, which will allow me to start putting the pieces together to make the whole.

https://www.instagram.com/p/BkPxjjcF5y3/?taken-by=levantebrewing

There is a delicate balance between the malt/grain bill, the hops, the yeast and any other flavor additions so there is not one set way to build the entirety of the recipe. But, I think the best way to describe it is that you pick your focal and most important flavor component that you are looking to achieve with this beer. You ask, “Is that an interesting hop or malt profile, or will this be a yeast or fruit-forward beer?” Then, you work off of that to balance and accentuate those key flavors which you are looking for. The balance of those flavors is the most important thing to do, and may be the hardest because you want to set up an expectation for your customer. But, then you also want to meet and exceed that expectation to create a unique moment for them when they taste it.

How, and from where, do you source the ingredients?

For the most part, on our production side, we source our grain and malt from craft brewing supply groups, Country Malt Group and Brewers Supply Group. But, when we can, we are lucky to have Deer Creek Malthouse a few miles away and have been able to do some fun beers with their craft malt. Unfortunately, we do not get to use their malt as much as we would like.

For our hops, we get 80% of our hops from this awesome hop farm/supplier called Crosby Hop Farm, out of Woodburn, Oregon. We happen to think they have some of the best hops in the world! We have also been lucky enough to get some fruit and other local products from Highland Orchards in West Chester. We just did a strawberry and rhubarb grisette with some freshly harvested rhubarb, which was amazing. We hope to open that relationship up some more and utilize their local fruit in some more of our beers as we head into the end of the summer and fall.

What is the step-by-step brewing process?

The first thing we do is grind our grain, which essentially removes the husk from the grain kernel and cracks the kernel, which provides access to all of the necessary sugars needed to make beer. Then, we mix that grain with hot water to extract the flavor, color and sugar content.

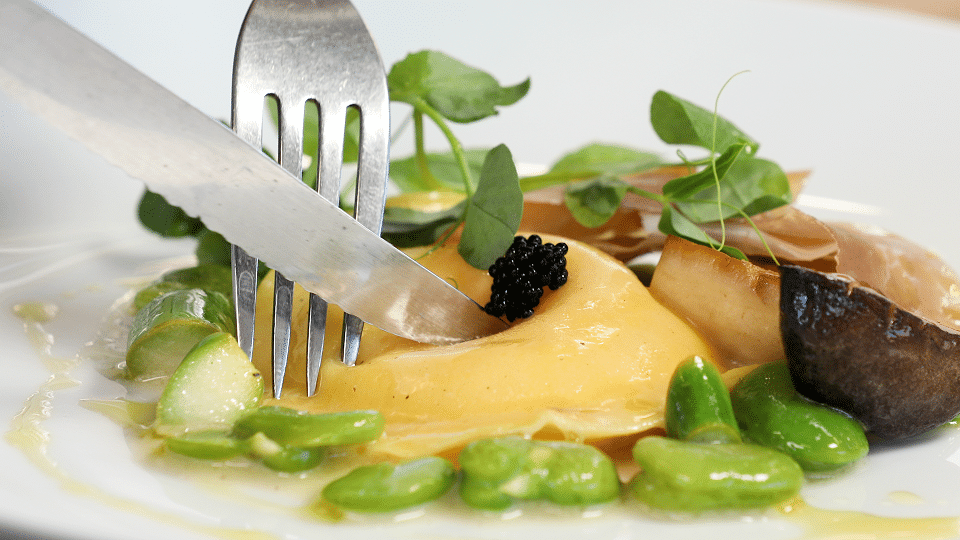

Once we have done that, we move that sugary liquid (which is called wort) into our kettle and boil it. This is where we add any hops or other flavor additions we may want, like herbs and spices. After about an hour of boiling, we rapidly chill the wort with a plate chiller down to around 68 degrees Fahrenheit and move the wort into one of our fermenting vessels, where we can combine it with various types of yeast, depending on the beer.

Yeast is another flavor component to the beer, as the different strains you can use can create a variety of flavors, but the main function of yeast is to eat up the sugars in the wort, which will convert those sugars into the alcohol content of the beer. This is called fermentation.

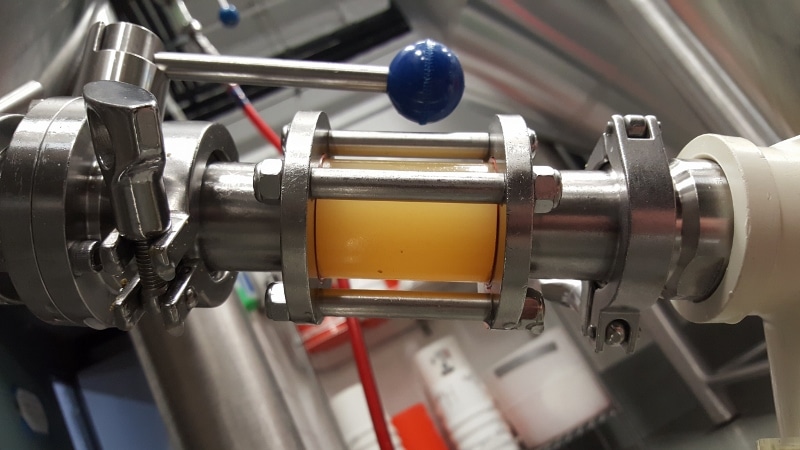

After about 10 days, the beer should be fully fermented and we use glycol jackets, which line our fermenting vessels to “cold crash” our beer. This drops the temp from about 68 to 34 degrees in a day or so. We hold it at this temperature for a couple of days and this will allow any yeast, hop or protein solids to settle out and we can remove off the bottom of the vessel. Once it has been cold crashed for a few days, the majority of the time we will move the beer into one of our brite conditioning tanks, where it will continue to sit cold, and we will add CO2 right into the liquid to create the carbonation level we desire for consumption. From the brite conditioning tanks, the beer moves into kegs where it will then go to bars or our taproom to sell to customers.

How and where are the products packaged?

As I mentioned above, we package all of our kegs on site. Our canned products we also package on site, but we utilize a mobile canning company which comes in every two weeks, sets up the canning machine and cans some of our products. We also do small-batch bottling runs using a four-head bottling machine we made ourselves.

How do you go about selling and distributing the new brews?

Our kegged beers we sell through our on-site taproom and through our sales team and wholesaler. Our taproom has 20 taps, so we fill them up with a variety of different beers. We like to curate our tap list, like a restaurant would with their food menu. We like to have a variety of styles on tap at all times, so that when people come in they have a unique beer experience to what they have had at other places. Also, we like having the variety so we always have an option for any type of beer consumer, including someone who is looking to try beers they may have never had before.

On the wholesale/distribution side of our business, which supplies bars, restaurants, etc., we have a great team of salespeople doing an amazing job selling our beers to our market. We work with them and our taproom team members to also ensure that the production team and the brewers are creating the best possible products which the customers are looking for.

Thank you to Greg Harris for taking the time to go through the brewing process with us. Be sure to visit Levante Brewing Company in West Chester ASAP for unique brews and a stellar team who will help you to choose the right beer to appeal to your tastes!

Find Levante Brewing Co. at 208 Carter Dr., Suite 2 in West Chester; phone: (484) 999-8761.

- Malt photo: Deer Creek Malt

- All other photos: Levante Brewing Company